Products

Anti-Theft Oil Monitoring Technologies for Oil PipYou are here: Home > Products > Anti-Theft Oil Monitoring Technologies for Oil Pip > Anti-Theft Oil Monitoring Technologies for Oil Pip

Anti-Theft Oil Monitoring Technologies for Oil Pip

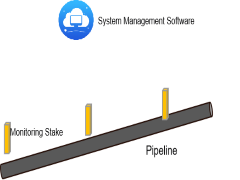

Acoustic Wave Monitoring

The system consists of management software, monitoring stakes, and sensors, which are arrayed and buried along the pipeline;

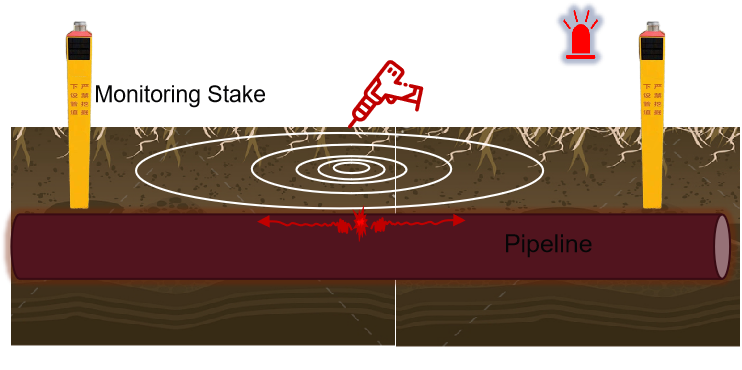

When the pipeline experiences abnormal vibrations such as drilling, the sound waves propagate along the pipeline and can be detected;

Multiple monitoring stakes and sensors form an array, enabling precise location of the oil theft site.

Installation Method

Monitoring stakes are buried underground, and sensors are installed closely against the pipeline wall;

Multiple monitoring stakes and sensors are installed at intervals of 100-300 meters

System Function

Communication Methods: NB-IoT/4G, Beidou /GPS;

Dimensions: 150*150*1200mm;

Power Supply: Lithium battery >6 months, rechargeable;

Protection Level: IP67;

Operating Temperature: -20~70℃;

Monitoring Distance: Typical 200m (depending on pipeline conditions);

Positioning Accuracy: ±5m;

Tamper Alarm Function

Negative Pressure Wave :

When tapping pipelines and stealing oil, the instantaneous decrease in fluid density leads to a decrease in pressure, forming negative pressure waves. This wave can be detected by pressure sensors at both ends of the pipeline to determine the leakage and its location.

Distributed Fiber Optical Sensing (DAS):

During the process of pipeline tapping for oil theft, vibrations are produced. These vibrations cause changes in the light transmitted through the fiber cables laid on the pipeline. By monitoring these changes, pipeline damage and its location can be determined. The fiber cables must be laid along the pipeline, usually employing DAS technology.

LinkedIn

LinkedIn Facebook

Facebook